- Email: sales@xinfengcable.com

- WhatsApp: + 86 1 3333 8683 99

Conducting The Energy - Xinfeng Cable

XHHW/XHHW-2 Cable is a designation for specific electrical wire and cable

XHHW is an alphabetism or initialism which stands for “XLPE (cross-linked polyethylene) High Heatresistant Water-resistant.” XHHW is a designation for a specific insulation material, temperature rating, and condition of use (suitable for wet locations) for electrical wire and cable. Wires with XHHW insulation are commonly used in the alternating current (AC) electrical distribution systems of commercial, institutional, and industrial buildings and installations, usually at voltage levels (potential difference or electromotive force) ranging from 110-600 Volts. This type of insulation is used for both copper and aluminum conductors which are either solid or stranded, depending on size. According to Underwriters Laboratories (UL) Standard 44, XHHW insulation is suitable for use in dry locations up to 90° C (194° F), or wet locations up to 75° C (167° F).

XHHW-2 insulation, which is similar to XHHW, is suitable for use in dry or wet locations up to 90° C (194° F).

UL 44 ,ASTM-B3,ASTM B 230 , ASTM B 231 ,ASTM B 800 , ASTM B 801 ,ASTM-B787,NEMA WC70/ICEA S-95-658.

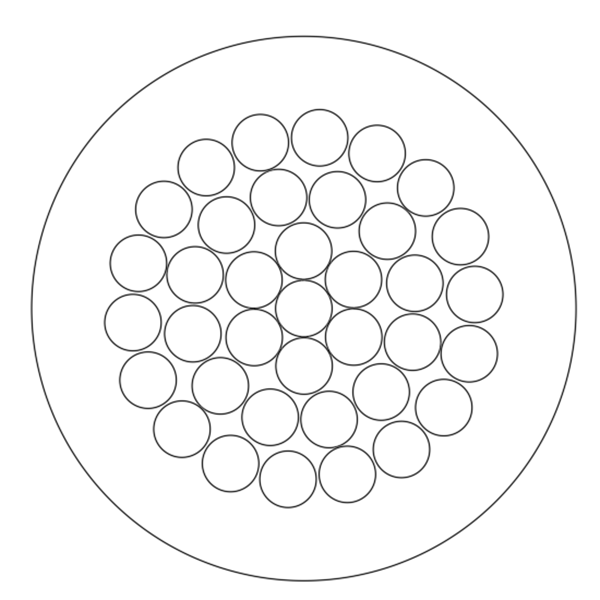

Conductor: Plain annealed copper conductor or aluminium or aluminium alloy 8000 series

Insulation: Crosslinked polyethylene(XLPE). High heat-resistant, water-resistant.

| Size AWG or MCM |

Conductor Construction | Approx. Overall Diameter mm |

Approx. Weight of Cable(CU) kg/km |

Approx. Weight of Cable(AL/AL ALLOY) kg/km |

Maximum Conductor DC Resistance 20℃(CU) Ω/km |

Maximum Conductor DC Resistance 20℃(AL/AL ALLOY) Ω/km |

| No. of Strands | ||||||

| 14 | solid | 3.15 | 24 | / | 8.45 | / |

| 12 | solid | 3.58 | 36 | / | 5.31 | / |

| 10 | solid | 4.11 | 55 | / | 3.343 | / |

| 8 | solid | 5.55 | 91 | / | 2.102 | / |

| 6 | solid | 6.4 | 138 | / | 1.322 | / |

| 14 | 7 | 3.37 | 26 | / | 8.63 | / |

| 12 | 7 | 3.85 | 39 | / | 5.46 | / |

| 10 | 7 | 4.46 | 58 | / | 3.42 | / |

| 8 | 7 | 5.99 | 96 | / | 2.144 | / |

| 6 | 7 | 6.95 | 146 | 62 | 3.348 | 2.211 |

| 4 | 7 | 8.04 | 220 | 86 | 0.8481 | 1.39 |

| 3 | 7 | 8.75 | 274 | 103 | 0.673 | 1.1 |

| 2 | 7 | 9.54 | 341 | 128 | 0.5335 | 0.8745 |

| 1 | 19 | 10.94 | 434 | 164 | 0.423 | 0.6934 |

| 1/0 | 19 | 11.94 | 541 | 199 | 0.3354 | 0.5498 |

| 2/0 | 19 | 13.07 | 674 | 243 | 0.266 | 0.4361 |

| 3/0 | 19 | 14.33 | 842 | 298 | 0.211 | 0.345 |

| 4/0 | 19 | 15.75 | 1053 | 368 | 0.167 | 0.277 |

| 250 | 37 | 17.93 | 1247 | 440 | 0.141 | 0.232 |

| 300 | 37 | 19.33 | 1486 | 519 | 0.118 | 0.1935 |

| 350 | 37 | 20.62 | 1725 | 597 | 0.1011 | 0.1659 |

| 400 | 37 | 21.82 | 1963 | 673 | 0.0886 | 0.145 |

| 500 | 37 | 24 | 2439 | 827 | 0.0787 | 0.1289 |

| 600 | 61 | 26.75 | 2946 | 1010 | 0.059 | 0.0968 |

| 750 | 61 | 29.44 | 3660 | 1240 | 0.0473 | 0.0774 |

| 1000 | 61 | 33.35 | 4845 | 1622 | 0.0354 | 0.058 |

If you have any interested in our cable product, welcome to get in touch with us!