- Email: sales@xinfengcable.com

- WhatsApp: + 86 1 3333 8683 99

Conducting The Energy - Xinfeng Cable

ACAR Bare Conductor spplied from China Factory.

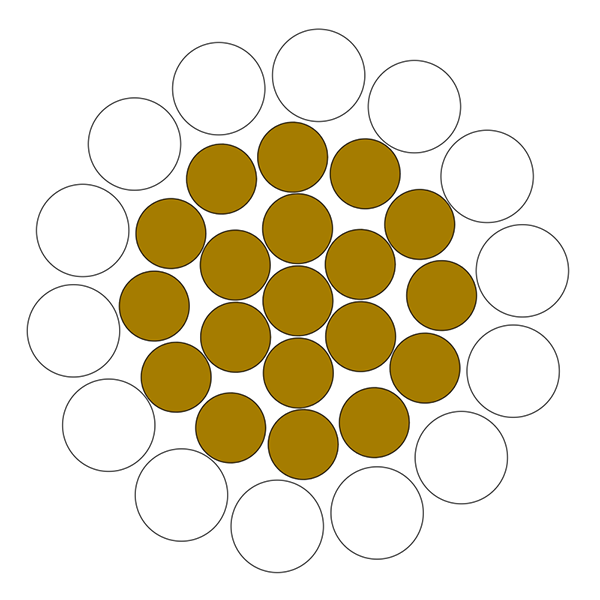

Used as bare overhead transmission cable and as primary and secondary distribution cable. A good strength-to-weight ratio makes ACAR applicable where both ampacity and strength are prime considerations in line design; for equal weight, ACAR offers higher strength and ampacity than ACSR.

Seismic Acceleration:0.12 – 0.05g

Ambient Temperature: -5°C – 50°C

Wind Pressure: 80 – 130kg/m2

Isokeraunic Level: 10 – 18

Relative Humidity: 5 – 100%

| Code | No. of Single wires | Diameter | Area | Approximate weight kg/km |

Maximum DC Resistance at 20℃ Ω/km |

||||

| AL | AL alloy | Single wire mm |

Conductor mm |

AL mm2 |

AL alloy mm2 |

Total mm2 |

|||

| 16 | 4 | 3 | 1.76 | 5.29 | 9.78 | 7.33 | 17.1 | 46.8 | 1.7896 |

| 25 | 4 | 3 | 2.21 | 6.62 | 15.3 | 11.5 | 26.7 | 73.1 | 1.1453 |

| 40 | 4 | 3 | 2.79 | 8.37 | 24.4 | 18.3 | 42.8 | 117 | 0.7158 |

| 63 | 4 | 3 | 3.5 | 10.5 | 38.5 | 28.9 | 67.4 | 184.3 | 0.4545 |

| 100 | 4 | 3 | 4.41 | 13.2 | 61.1 | 45.8 | 107 | 292.5 | 0.2863 |

| 125 | 12 | 7 | 2.98 | 14.9 | 84 | 48.8 | 132 | 364.1 | 0.2302 |

| 165 | 12 | 7 | 3.37 | 16.9 | 107 | 62.5 | 170 | 466 | 0.1798 |

| 200 | 12 | 7 | 3.77 | 18.8 | 134 | 78.1 | 212 | 582.5 | 0.1439 |

| 250 | 12 | 7 | 4.21 | 21.1 | 167 | 97.6 | 265 | 728.1 | 0.1151 |

| 250 | 18 | 19 | 3.05 | 21.4 | 132 | 139 | 271 | 746 | 0.1154 |

| 315 | 30 | 7 | 3.34 | 23.4 | 263 | 61.4 | 325 | 894.4 | 0.0916 |

| 315 | 18 | 19 | 3.43 | 24 | 166 | 175 | 341 | 940 | 0.0916 |

| 400 | 30 | 7 | 3.77 | 26.4 | 334 | 78 | 412 | 1135.8 | 0.0721 |

| 400 | 18 | 19 | 3.86 | 27 | 211 | 222 | 433 | 1193.7 | 0.0721 |

| 450 | 30 | 7 | 3.99 | 28 | 376 | 87.7 | 464 | 1277.8 | 0.0641 |

| 450 | 18 | 19 | 4.1 | 28.7 | 237 | 250 | 487 | 1342.9 | 0.0641 |

| 500 | 30 | 7 | 4.21 | 29.5 | 418 | 97.5 | 515 | 1419.8 | 0.0577 |

| 500 | 18 | 19 | 4.32 | 30.2 | 263 | 278 | 542 | 1492.1 | 0.0577 |

| 560 | 30 | 7 | 4.46 | 31.2 | 468 | 109 | 577 | 1590.1 | 0.0515 |

| 560 | 54 | 7 | 3.45 | 31.1 | 505 | 65.5 | 570 | 1573.9 | 0.0516 |

| 630 | 42 | 19 | 3.72 | 33.4 | 456 | 206 | 662 | 1826 | 0.0458 |

| 630 | 24 | 37 | 3.8 | 34.2 | 272 | 420 | 692 | 1909 | 0.0458 |

| 710 | 42 | 19 | 3.95 | 35.5 | 514 | 232 | 746 | 2057.8 | 0.0407 |

| 710 | 24 | 37 | 4.03 | 36.3 | 307 | 473 | 780 | 2151.4 | 0.0407 |

| 800 | 42 | 19 | 4.19 | 37.7 | 579 | 262 | 840 | 2318.7 | 0.0361 |

| 800 | 24 | 37 | 4.28 | 38.5 | 346 | 533 | 879 | 2424.2 | 0.0361 |

| 900 | 42 | 19 | 4.44 | 40 | 651 | 294 | 945 | 2608.5 | 0.0321 |

| 900 | 54 | 37 | 3.66 | 40.3 | 569 | 390 | 959 | 2649.5 | 0.0321 |

| 1000 | 72 | 19 | 3.8 | 41.8 | 818 | 216 | 1034 | 2855.4 | 0.0289 |

| 1000 | 54 | 37 | 3.86 | 42.5 | 632 | 433 | 1066 | 2943.9 | 0.0289 |

| 1120 | 72 | 19 | 4.02 | 44.3 | 916 | 242 | 1158 | 3198.1 | 0.0258 |

| 1120 | 54 | 37 | 4.09 | 45 | 708 | 485 | 1194 | 3297.2 | 0.0258 |

| 1250 | 72 | 19 | 4.25 | 46.8 | 1022 | 270 | 1292 | 3569.3 | 0.0231 |

| 1250 | 54 | 37 | 4.32 | 47.5 | 791 | 542 | 1332 | 3679.9 | 0.0231 |

| 1400 | 72 | 19 | 4.5 | 49.5 | 1145 | 302 | 1447 | 3997.6 | 0.0207 |

If you have any interested in our cable product, welcome to get in touch with us!