- Email: sales@xinfengcable.com

- WhatsApp: + 86 1 3333 8683 99

Conducting The Energy - Xinfeng Cable

Overhead No insulated Aluminium-alloy Conductor from China

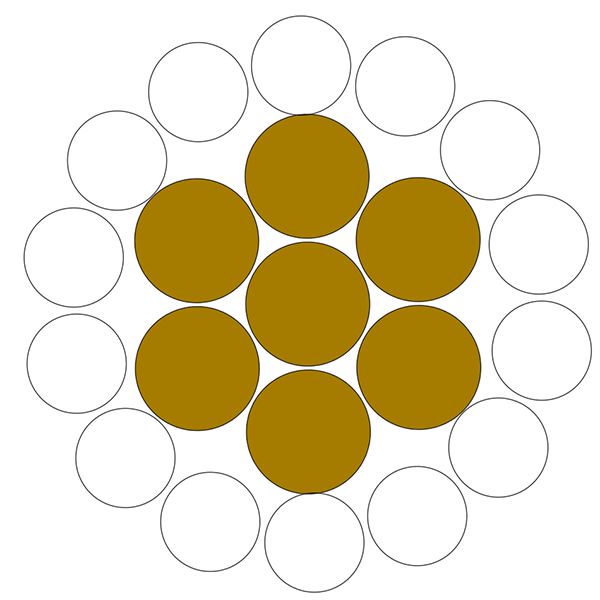

TACSR Conductors are very similar in construction to a conventional ACSR conductor but the EC Grade Aluminum wires are replaced with Hard Drawn Aluminum wires of Heat Resistant Aluminum Alloy (generally known as TAL ) . TACSR can be safely operated continuously above 150℃ enabling to pump more current through the conductor. Where there is a need to transmit higher power but restrictions on getting new power corridors approved, various Types of TAL conductors are one of the best creative solution options to utilities. Ability of the Zirconium doped aluminum alloy to maintain its electrical and mechanical properties at elevated temperatures makes these conductors a very cost effective solution in refurbishing the existing lines with enhanced capacity.

TACSR (/AW) is used for overhead electric power transmission lines. Big city, seaside district, moisture area etc.

IEC 62004 Thermal-resistant aluminium-alloy wire for overhead line conductor

Core(St, AW): Galvanized Steel Wire / Aluminum-clad Steel Wire(AW) : 14% ~ 40% AW

Conductor(TAI) : Thermal Resistant Aluminum Alloy Wire used for continuously allowable temperature up to 150℃

| Nominal Section Area mm2 |

Stranding | Area | Diameter | Approximate weight | |||

| No./Diameter | |||||||

| Structure | |||||||

| TAL Wire mm |

ST Wire mm |

TAL Wire mm2 |

ST Wire mm2 |

Total mm2 |

Conductor mm |

Total kg/km |

|

| 58 | 6/3.5 | 1/3.5 | 57.73 | 9.52 | 67.35 | 10.5 | 233.1 |

| 80 | 6/4.2 | 1/4.2 | 83.13 | 13.85 | 96.98 | 12.6 | 335.5 |

| 80 | 15/2.6 | 4/2.6 | 79.64 | 21.24 | 100.88 | 13 | 385.7 |

| 95 | 6/4.5 | 1/4.5 | 95.43 | 15.9 | 111.33 | 13.5 | 385.2 |

| 100 | 15/2.9 | 4/2.9 | 99.08 | 26.42 | 125.5 | 14.5 | 479.9 |

| 120 | 15/3.2 | 4/3.2 | 120.64 | 32.17 | 152.81 | 16 | 584.4 |

| 120 | 30/2.3 | 7/2.3 | 124.64 | 29.08 | 153.72 | 16.1 | 573.7 |

| 160 | 30/2.6 | 7/2.6 | 159.28 | 37.17 | 196.45 | 18.2 | 732.8 |

| 200 | 30/2.9 | 7/2.9 | 198.16 | 46.24 | 244.4 | 20.3 | 911.7 |

| 240 | 30/3.2 | 7/3.2 | 241.27 | 56.3 | 297.57 | 22.4 | 1,110 |

| 330 | 26/4.0 | 7/3.1 | 326.73 | 52.83 | 379.56 | 25.3 | 1,320 |

| 410 | 26/4.5 | 7/3.5 | 413.51 | 67.35 | 480.86 | 28.5 | 1,673 |

| 480 | 45/3.7 | 7/2.47 | 483.8 | 33.54 | 517.34 | 29.6 | 1,599 |

| 520 | 54/3.5 | 7/3.5 | 519.54 | 67.35 | 586.89 | 31.5 | 1,969 |

| 610 | 54/3.8 | 7/3.8 | 612.42 | 79.39 | 691.81 | 34.2 | 2,320 |

| 680 | 54/4.0 | 7/4.0 | 678.58 | 87.96 | 766.54 | 36 | 2,572 |

| 680 | 45/4.4 | 7/2.9 | 684.24 | 46.24 | 730.48 | 35.1 | 2,260 |

| 810 | 45/4.8 | 7/3.2 | 814.3 | 56.3 | 870.6 | 38.4 | 2,700 |

| 1160 | 84/4.2 | 7/4.2 | 1163.77 | 96.98 | 1,260.75 | 46.2 | 3,996 |

| 1520 | 84/4.8 | 7/4.8 | 1520.03 | 126.67 | 1,646.70 | 52.8 | 5,222 |

| Nominal Section Area mm2 |

Stranding | Area | Diameter | Approximate weight | |||

| No./Diameter | |||||||

| Structure | |||||||

| TAL Wire mm |

ST Wire mm |

TAL Wire mm2 |

ST Wire mm2 |

Total mm2 |

Conductor mm |

Total kg/km |

|

| 120 | 30/2.3 | 7/2.3 | 124.7 | 29.08 | 153.78 | 16.1 | 541 |

| 160 | 30/2.6 | 7/2.6 | 159.3 | 37.16 | 196.46 | 18.2 | 691 |

| 200 | 30/2.9 | 7/2.9 | 198.2 | 46.24 | 244.44 | 20.3 | 860 |

| 210 | 30/3.2 | 7/3.2 | 241.3 | 56.29 | 297.59 | 22.4 | 1047 |

| 330 | 26/4.0 | 7/3.1 | 326.8 | 52.84 | 379.64 | 25.3 | 1260 |

| 410 | 26/4.5 | 7/3.5 | 413.4 | 67.35 | 480.75 | 28.5 | 1598 |

| 480 | 45/3.7 | 7/2.47 | 483.84 | 33.54 | 517.38 | 29.6 | 1566 |

| 520 | 54/3.5 | 7/3.5 | 519.5 | 67.35 | 586.85 | 31.5 | 1892 |

| 610 | 54/3.8 | 7/3.8 | 612.4 | 79.38 | 691.78 | 34.2 | 2230 |

| 680 | 45/4.4 | 7/2.9 | 684.5 | 46.24 | 730.74 | 35.1 | 2207 |

| 810 | 45/4.8 | 7/3.2 | 814.5 | 56.29 | 870.79 | 38.4 | 2635 |

| 950 | 84/3.8 | 7/3.8 | 952.6 | 79.38 | 1031.98 | 41.8 | 3173 |

| 1,160 | 84/4.2 | 7/4.2 | 1,163 | 96.95 | 1259.95 | 46.2 | 3876 |

| 1,520 | 84/4.8 | 7/4.8 | 1,520 | 126.7 | 1646.7 | 52.8 | 5063 |

| Nominal Section Area mm2 |

Stranding | Area | Diameter | Approximate weight | |||

| No./Diameter | |||||||

| Structure | |||||||

| TAL Wire mm |

ST Wire mm |

TAL Wire mm2 |

ST Wire mm2 |

Total mm2 |

Conductor mm |

Total kg/km |

|

| 120 | 30/2.3 | 7/2.3 | 124.7 | 29.08 | 153.78 | 16.1 | 531 |

| 160 | 30/2.6 | 7/2.6 | 159.3 | 37.16 | 196.46 | 18.2 | 679 |

| 200 | 30/2.9 | 7/2.9 | 198.2 | 46.24 | 244.44 | 20.3 | 845 |

| 210 | 30/3.2 | 7/3.2 | 241.3 | 56.29 | 297.59 | 22.4 | 1029 |

| 330 | 26/4.0 | 7/3.1 | 326.8 | 52.84 | 379.64 | 25.3 | 1243 |

| 410 | 26/4.5 | 7/3.5 | 413.4 | 67.35 | 480.75 | 28.5 | 1576 |

| 480 | 45/3.7 | 7/2.47 | 483.84 | 33.54 | 517.38 | 29.6 | 1555 |

| 520 | 54/3.5 | 7/3.5 | 519.5 | 67.35 | 586.85 | 31.5 | 1870 |

| 610 | 54/3.8 | 7/3.8 | 612.4 | 79.38 | 691.78 | 34.2 | 2204 |

| 680 | 45/4.4 | 7/2.9 | 684.5 | 46.24 | 730.74 | 35.1 | 2191 |

| 810 | 45/4.8 | 7/3.2 | 814.5 | 56.29 | 870.79 | 38.4 | 2616 |

| 950 | 84/3.8 | 7/3.8 | 952.6 | 79.38 | 1031.98 | 41.8 | 3147 |

| 1,160 | 84/4.2 | 7/4.2 | 1,163 | 96.95 | 1259.95 | 46.2 | 3845 |

| 1,520 | 84/4.8 | 7/4.8 | 1,520 | 126.7 | 1646.7 | 52.8 | 5021 |

If you have any interested in our cable product, welcome to get in touch with us!