- Email: sales@xinfengcable.com

- WhatsApp: + 86 1 3333 8683 99

Conducting The Energy - Xinfeng Cable

450/750V Electrical cable EPR cable manufacturer

These cables are designed to provide high flexibility and have the capacity to withstand weather, oil/grease, mechanical and thermal stresses. Applications include handling equipment, mobile power supplies, worksites, stage and audiovisual equipment, port areas and dams. Also for use in drainage and water treatment, cold environments and severe industrial environments.

IEC 60245, BS EN 50525-2-21, GB/T5013.4 etc.

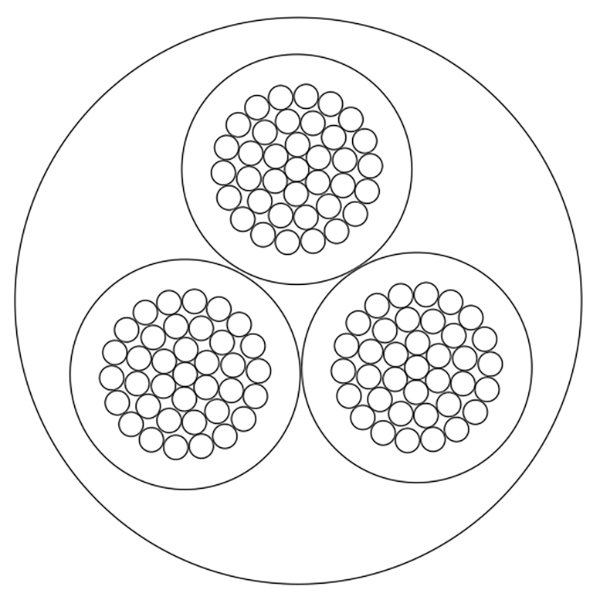

Conductor: Plain annealed flexible copper wire or tinned annealed flexible copper wire (Class 5)

Insulation: EPR (Ethylene Propylene Rubber) or other equivalent synthetic elastomer

Sheath: Polychloroprene compound (PCP) or other equivalent synthetic elastomer

| Core and size mm2 |

Stranding number of strand/strand diameter No./mm |

Thickness of insulation mm |

Thickness of sheath mm |

Nominal overall diameter mm |

Approx. weight kg/km |

| 1×1.5 | 30×0.25 | 0.8 | 1.4 | 6 | 49 |

| 1x 2.5 | 50×0.25 | 0.9 | 1.4 | 6.6 | 63 |

| 1×4 | 56×0.30 | 1 | 1.5 | 7.6 | 92 |

| 1×6 | 84×0.30 | 1 | 1.6 | 8.3 | 115 |

| 1×10 | 80×0.40 | 1.2 | 1.8 | 10.7 | 189 |

| 1×16 | 126×0.40 | 1.2 | 1.9 | 12 | 260 |

| 1×25 | 196×0.40 | 1.4 | 2 | 14.1 | 369 |

| 1×35 | 276×0.40 | 1.4 | 2.2 | 15.8 | 500 |

| 1×50 | 396×0.40 | 1.6 | 2.4 | 18.3 | 689 |

| 1×70 | 360×0.50 | 1.6 | 2.6 | 20.7 | 918 |

| 1×95 | 475×0.50 | 1.8 | 2.8 | 23.4 | 1202 |

| 1×120 | 608×0.50 | 1.8 | 3 | 25.6 | 1489 |

| 1×150 | 756×0.50 | 2 | 3.2 | 28.3 | 1824 |

| 1×185 | 925×0.50 | 2.2 | 3.4 | 31 | 2202 |

| 1×240 | 1221×0.50 | 2.4 | 3.5 | 34.5 | 2847 |

| 1×300 | 1525×0.50 | 2.6 | 3.6 | 37.7 | 3495 |

| 1×400 | 2013×0.50 | 2.8 | 3.8 | 40.4 | 4293 |

| 1×500 | 1769×0.60 | 3 | 4 | 42.6 | 5262 |

| 1×630 | 2257×0.60 | 3 | 4.1 | 47.2 | 6790 |

| 2 X 1.0 | 32/0.20 | 0.8 | 1.3 | 8.4 | 98 |

| 2 X 1.5 | 30/0.50 | 0.8 | 1.5 | 9.4 | 116 |

| 2 X 2.5 | 50/0.25 | 0.9 | 1.7 | 11 | 164 |

| 2 X 4 | 56/0.30 | 1 | 1.8 | 12.8 | 232 |

| 2 X 6 | 84/0.30 | 1 | 2 | 14.2 | 297 |

| 2 X 10 | 80/0.40 | 1.2 | 3.1 | 20.4 | 573 |

| 2 X 16 | 126/0.40 | 1.2 | 3.3 | 23 | 774 |

| 2 X 25 | 196/0.40 | 1.4 | 3.6 | 27.4 | 1110 |

| 2 X 35 | 276/0.40 | 1.4 | 3.8 | 30.8 | 1474 |

| 3 X 1.0 | 32/0.20 | 0.8 | 1.4 | 9 | 108 |

| 3 X 1.5 | 30/0.50 | 0.8 | 1.6 | 10.3 | 141 |

| 3 X 2.5 | 50/0.25 | 0.9 | 1.8 | 11.8 | 200 |

| 3 X 4 | 56/0.30 | 1 | 1.9 | 13.7 | 285 |

| 3 X 6 | 84/0.30 | 1 | 2.1 | 15.2 | 371 |

| 3 X 10 | 80/0.40 | 1.2 | 3.3 | 21.9 | 712 |

| 3 X 16 | 126/0.40 | 1.2 | 3.5 | 24.7 | 971 |

| 3 X 25 | 196/0.40 | 1.4 | 3.8 | 29.4 | 1394 |

| 4 X 1.0 | 32/0.20 | 0.8 | 1.5 | 10 | 134 |

| 4 X 1.5 | 30/0.25 | 0.8 | 1.7 | 11.2 | 174 |

| 4 X 2.5 | 50/0.25 | 0.9 | 1.9 | 12.6 | 249 |

| 4 X 4 | 56/0.30 | 1 | 2 | 15.1 | 361 |

| 4 X 6 | 84/0.30 | 1 | 2.3 | 16.9 | 480 |

| 4 X 10 | 80/0.40 | 1.2 | 3.4 | 24 | 890 |

| 4 X 16 | 126/0.40 | 1.2 | 3.6 | 27 | 1225 |

| 4 X 25 | 196/0.40 | 1.4 | 4.1 | 32.6 | 1792 |

| 4 X 35 | 276/0.4 | 1.4 | 4.4 | 36.5 | 2380 |

| 4 X 50 | 396/0.4 | 1.6 | 4.8 | 42 | 3635 |

| 4 X 70 | 360/0.5 | 1.6 | 5.2 | 49 | 4830 |

| 4 X 95 | 475/0.5 | 1.8 | 5.9 | 55 | 6320 |

| 5 X 1.0 | 32/0.20 | 0.8 | 1.6 | 11 | 170 |

| 5 X 1.5 | 30/0.50 | 0.8 | 1.8 | 12.3 | 218 |

| 5 X 2.5 | 50/0.25 | 0.9 | 2 | 14.5 | 309 |

| 5 X 4 | 56/0.30 | 1 | 2.2 | 16.9 | 450 |

| 5 X 6 | 84/0.30 | 1 | 2.5 | 18.8 | 595 |

| 5 X 10 | 80/0.40 | 1.2 | 3.6 | 26.5 | 1100 |

| 5 X 16 | 126/0.40 | 1.2 | 3.9 | 30 | 1528 |

| 5 X 25 | 196/0.40 | 1.4 | 4.4 | 36 | 2200 |

| 5 X 35 | 276/0.40 | 1.4 | 4.6 | 40 | 2925 |

If you have any interested in our cable product, welcome to get in touch with us!