- Email: sales@xinfengcable.com

- WhatsApp: + 86 1 3333 8683 99

Conducting The Energy - Xinfeng Cable

H01N2-D Flexible copper wire rubber cable

These cables are used as a connection to welding robots in the automotive industry, shipyards and for manually/automatically operated lines and spot welding. The robust cable structure makes them resistant to low and high temperatures, ozone and radiation, oils, acids, fats and petrols.

IEC 60245、 GB/T5013.6 、BS EN 50525-2-81 、DIN、 VDE etc.

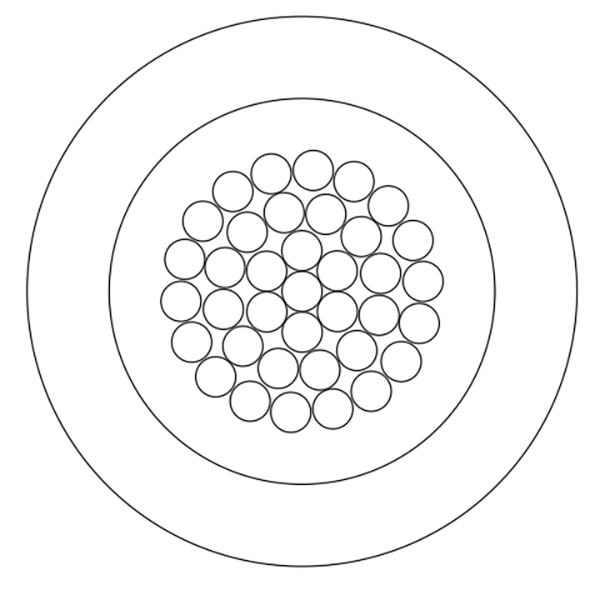

Conductor: Plain annealed flexible copper wire (Class 6, according to BS EN 60228)

Separator: PET (Polyester Tape)

Sheath: Rubber compound, Type EM5 according to BS EN 50363, the cover can consist of one or two layer.

| Nominal Cross-sectional area mm2 |

Max. Diameter of wire mm |

Nominal Thickness of Sheath mm |

Average Overall Diameter mm |

Maximum DC Resistance at 20℃ Ω/km |

||

| Min. | Max. | Tinned copper | Untinned copper | |||

| 10 | 0.21 | 1.2 | 6.2 | 7.8 | 1.95 | 1.91 |

| 16 | 1.2 | 7.3 | 9.1 | 1.24 | 1.21 | |

| 25 | 1.2 | 8.6 | 10.8 | 0.795 | 0.78 | |

| 35 | 1.2 | 9.8 | 12.3 | 0.565 | 0.554 | |

| 50 | 1.5 | 11.9 | 14.8 | 0.393 | 0.386 | |

| 70 | 1.5 | 13.6 | 17 | 0.277 | 0.272 | |

| 95 | 1.8 | 15.6 | 19.5 | 0.21 | 0.206 | |

| 120 | 1.8 | 17.2 | 21.6 | 0.164 | 0.161 | |

| 150 | 1.8 | 18.8 | 23.5 | 0.132 | 0.129 | |

| 185 | 1.8 | 20.4 | 25.5 | 0.108 | 0.106 | |

If you have any interested in our cable product, welcome to get in touch with us!