- Email: sales@xinfengcable.com

- WhatsApp: + 86 1 3333 8683 99

Conducting The Energy - Xinfeng Cable

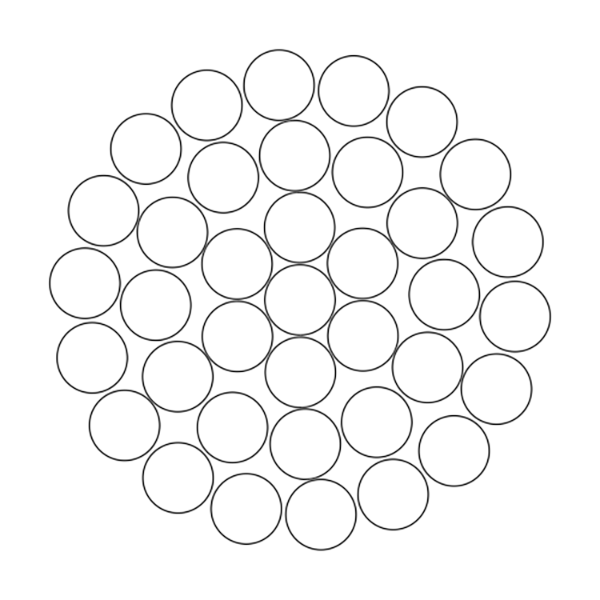

GSW Zinc-Coated Steel Conductor Overhead used

The galvanized steel wire strand is used for overhead ground lines or electrical power transmission lines. Stay or guy wire strands are produced for use with poles, towers, or any other form of guying.Galvanized steel wire strand in multi-core electrical cables. Its low cost and ease of production makes galvanized steel wire ideal for mass produced corrosion resistant wire products. It is an indispensable industrial, agricultural, and DIY fastening and reinforcement standard.

Including but not limited to:

Concentrically stranded Galvanized steel wire strand available in class “A”, “B” and “C” galvanizing, “A” being the least heavy and “C” being the most heavy. Manufactured without welds per ASTM A-363 or with welds per ASTM A-475. Strands are formed to remain substantially in place when severed.

Zinc-coated grade of steel strand wire /guy wire

Class A, B and C and Bezinal, a superior corrosive coating of 5% Aluminum and 95% Zinc.

| Number of Wires/Dia. | Approx.Strand Dia. | Siemem Martin Grade KN |

High Strength Grade KN |

Extra-high Strength Grade KN |

Approx.Weight kg/km |

|

| Inch | mm | |||||

| 3/2.64 | 7/32 | 5.56 | 10.409 | 15.569 | 21.796 | 131 |

| 3/3.05 | 1/4 | 6.35 | 13.523 | 21.04 | 29.981 | 174 |

| 3/3.05 | 1/4 | 6.35 | — | — | — | 174 |

| 3/3.30 | 9/32 | 7.14 | 15.035 | 23.398 | 33.362 | 204 |

| 3/3.68 | 5/16 | 7.94 | 18.193 | 28.246 | 40.479 | 256 |

| 3/4.19 | 3/8 | 9.52 | 24.732 | 37.187 | 52.489 | 328 |

| 7/1.04 | 1/8 | 3.18 | 4.048 | 5.916 | 8.18 | 49 |

| 7/1.32 | 5/32 | 3.97 | 6.539 | 9.519 | 13.078 | 76 |

| 7/1.57 | 3/16 | 4.76 | 8.452 | 12.677 | 17.748 | 108 |

| 7/1.65 | 3/16 | 4.76 | — | — | — | 118 |

| 7/1.83 | 3/16 | 5.56 | 11.387 | 17.126 | 24.02 | 145 |

| 7/2.03 | 7/32 | 6.35 | 14.012 | 21.129 | 29.581 | 181 |

| 7/2.36 | 1/4 | 7.14 | 18.905 | 28.469 | 39.812 | 243 |

| 7/2.64 | 9/32 | 7.94 | 23.798 | 35.586 | 49.82 | 305 |

| 7/2.77 | 5/16 | 7.94 | — | — | — | 335 |

| 7/3.05 | 3/8 | 9.52 | 30.915 | 48.04 | 68.503 | 407 |

| 7/3.68 | 7/16 | 11.11 | 41.591 | 64.499 | 92.523 | 594 |

| 7/4.19 | 1/2 | 12.7 | 53.823 | 83.627 | 119.657 | 768 |

| 7/4.78 | 9/16 | 14.29 | 69.837 | 108.981 | 155.688 | 991 |

| 7/5.26 | 5/8 | 15.88 | 84.961 | 131.667 | 188.605 | 1211 |

| 19/2.54 | 1/2 | 12.7 | 56.492 | 84.961 | 118.768 | 751 |

| 19/2.87 | 9/16 | 12.49 | 71.616 | 107.202 | 149.905 | 948 |

| 19/3.18 | 5/8 | 15.88 | 80.513 | 124.995 | 178.819 | 1184 |

| 19/3.81 | 3/4 | 19.05 | 116.543 | 181.487 | 259.331 | 1719 |

| 19/4.50 | 7/8 | 22.22 | 159.691 | 248.211 | 354.523 | 2352 |

| 19/5.08 | 1/1 | 25.4 | 209.066 | 325.61 | 464.839 | 2384 |

| 37/3.63 | 1/1 | 25.4 | 205.508 | 319.827 | 456.832 | 3061 |

| 37/4.09 | 11/8 | 28.58 | 262 | 407.457 | 581.827 | 4006 |

| 37/4.55 | 11/4 | 31.75 | 324.72 | 505.318 | 721.502 | 4833 |

| Number of Wires/Dia. | Approx. Conductor Dia. mm |

Minimum Breaking Load of Conductor | Approx. Weight kg/km |

||||||

| Grade 350 kN |

Grade 480 kN |

Grade 700 kN |

Grade 850 kN |

Grade 1000 kN |

Grade 1150 kN |

Grade 1300 kN |

|||

| 3/1.80 | 3.9 | 2.65 | 3.66 | – | – | – | – | – | 60 |

| 3/2.65 | 5.7 | 5.8 | 7.95 | – | – | – | – | – | 130 |

| 3/3.25 | 7 | 8.7 | 11.95 | – | – | – | – | – | 195 |

| 3/4.00 | 8.6 | 13.2 | 18.1 | – | – | – | – | – | 295 |

| 4/1.80 | 4.4 | 3.55 | 4.9 | – | – | – | – | – | 80 |

| 4/2.65 | 6.4 | 7.7 | 10.6 | – | – | – | – | – | 172 |

| 4/3.25 | 7.9 | 11.6 | 15.9 | – | – | – | – | – | 260 |

| 4/4.00 | 9.7 | 17.6 | 24.1 | 35.2 | – | – | – | – | 390 |

| 5/1.50 | 4.1 | 3.1 | 4.24 | 6.18 | – | – | – | – | 69 |

| 5/1.80 | 4.9 | 4.45 | 6.1 | 8.9 | – | – | – | – | 95 |

| 5/2.65 | 7.2 | 9.65 | 13.25 | 19.3 | – | – | – | – | 220 |

| 5/3.25 | 8.8 | 14.5 | 19.9 | 29 | – | – | – | – | 320 |

| 5/4.00 | 10.8 | 22 | 30.15 | 43.95 | – | – | – | – | 490 |

| 7/0.56 | 1.7 | 0.6 | 0.83 | 1.2 | – | 1.7 | 1.98 | 2.24 | 14 |

| 7/0.71 | 2.1 | 0.97 | 1.33 | 1.94 | – | 2.75 | 3.19 | 3.6 | 28 |

| 7/0.85 | 2.6 | 1.39 | 1.9 | 2.8 | – | 3.95 | 4.57 | 5.15 | 31 |

| 7/0.90 | 2.7 | 1.55 | 2.14 | 3..1 | – | 4.45 | 5.12 | 5.8 | 35 |

| 7/1.00 | 3 | 1.92 | 2.64 | 3.85 | – | 5.5 | 6.32 | 7.15 | 43 |

| 7/1.25 | 3.8 | 3.01 | 4.1 | 6 | – | 8.55 | 9.88 | 11.15 | 67 |

| 7/1.40 | 4.2 | 3.75 | 5.17 | 7.54 | 9.16 | 10.75 | 12.35 | 14 | 84 |

| 7/1.60 | 4.8 | 4.9 | 6.75 | 9.85 | 11.95 | 14.1 | 16.2 | 18.3 | 110 |

| 7/1.80 | 5.4 | 6.23 | 8.55 | 12.45 | – | 17.8 | 20.5 | 23.2 | 140 |

| 7/2.00 | 6 | 7.7 | 10.55 | 15.4 | – | 22 | 25.3 | 28.6 | 170 |

| 7/2.36 | 7.1 | 10.7 | 14.7 | 21.4 | – | 30.6 | 35.2 | 39.8 | 240 |

| 7/2.65 | 8 | 13.5 | 18.5 | 27 | – | 38.6 | 44.4 | 50.2 | 300 |

| 7/3.00 | 9 | 17.3 | 23.75 | 34.65 | – | 49.5 | 56.9 | 64.3 | 392 |

| 7/3.15 | 9.5 | 19.1 | 26.2 | 38.2 | – | 54.55 | 62.75 | 70.9 | 430 |

| 7/3.25 | 9.8 | 20.3 | 27.85 | 40.65 | – | 58.05 | 66.8 | 75.5 | 460 |

| 7/3.65 | 11 | 25.6 | 35.15 | 51.25 | – | 73.25 | 84.2 | 95.2 | 570 |

| 7/4.00 | 12 | 30.9 | 42.2 | 61.6 | – | 88 | 101 | 114 | 690 |

| 7/4.25 | 12.8 | 34.75 | 47.65 | 69.5 | – | 99.3 | 114 | 129 | 780 |

| 7/4.75 | 14 | 43.4 | 59.45 | 86.8 | – | 124 | 142.7 | 161.3 | 970 |

| 19/1.00 | 5 | 5.22 | 7.16 | 10.45 | – | 14.92 | 17.16 | 19.4 | 120 |

| 19/1.25 | 6.3 | 8.16 | 11.19 | 16.32 | – | 23.32 | 26.81 | 30.31 | 180 |

| 19/1.40 | 7 | 10.24 | 14.04 | 20.47 | – | 29.25 | 33.64 | 38.02 | 230 |

| 19/1.60 | 8 | 13.37 | 18.35 | 26.75 | – | 38.2 | 43.93 | 49.66 | 300 |

| 19/2.00 | 10 | 20.9 | 28.65 | 41.78 | 50.74 | 59.69 | 68.64 | 77.6 | 470 |

| 19/2.50 | 12.5 | 32.65 | 44.8 | 65.29 | 79.28 | 93.27 | 107.3 | 121.3 | 730 |

| 19/3.00 | 15 | 47 | 64.5 | 94 | 114.1 | 134.3 | 154.5 | 174.6 | 1050 |

| 19/3.55 | 17.8 | 65.8 | 90.27 | 131.6 | 159.9 | 188 | 216.3 | 244.5 | 1470 |

| 19/4.00 | 20 | 83.55 | 114.6 | 167.1 | 203 | 238.7 | 274.6 | 310.4 | 1870 |

| 19/4.75 | 23.8 | 117.85 | 161.4 | 235.7 | 286 | 336.7 | 387.2 | 437.7 | 2630 |

Galvanized steel wire strand refers to any steel wire product that has subjected to a galvanizing process to improve its resistance to corrosion.

This process typically involves dipping the finished wire product into a bath of heated zinc compound to form a scratch and corrosion resistant coating across the entire surface of the wire.

If you have any interested in our cable product, welcome to get in touch with us!